-

Alfa Laval AlfaCond condensers are specifically designed for condensing of vapour under vacuum. These plate surface condensers are ideal for use in applications such as vacuum condensers in evaporation systems, ethanol condensers in bioethanol plants, pan vapour condensers in sugar refineries, and as turbine condensers in small power plants. With its compact design, AlfaCond is easy to install where space is crucial.

More information

-

Alfa Laval AlfaQ™ heat exchangers are used for HVAC applications such as district cooling substations, ice-storage systems, data centers, and free cooling systems. The range is certified according to the AHRI Liquid to Liquid Heat Exchangers (LLHE) Certification Program which ensures thermal performance according to manufacturers’ published specifications. AHRI certification is the only global, third-party performance certification for plate heat exchangers.

More information

-

AlfaVap is a semi-welded heat exchanger designed for rising film evaporation systems involving medias with high concentration and viscosity or as thermosiphon reboiler. It is powerful, robust, thermal efficient and easy to serve.

More information

-

Alfa Laval BaseLine is a competitive range of gasketed plate-and-frame heat exchangers for simpler dairy, food, beverage, pharma and other hygienic and utility applications.

More information

-

Alfa Laval CB brazed heat exchangers offers several advantages over traditional heat exchangers used in industrial, HVAC and refrigeration installations.

More information

-

Alfa Laval Diabon combines the highly efficient heat transfer ability of a compact plate heat exchanger with an exceptional corrosion resistance in a graphite material. The Diabon™ range offers an ideal solution for duties where metallic, glass or Teflon® plates don’t match the requirements for a corrosion resistant, easy serviceable and thermally efficient heat exchanger.

More information

-

Alfa Laval DOC (dedicated oil cooler) brazed plate heat exchangers provide the same efficient heat transfer and compact construction as our CB models, but with a design that is specifically engineered for oil cooling applications. With a reinforced flange connection that withstands high vibrations, DOC units can reliably handle heavy mechanical loads that accompany engine and hydraulic applications.

More information

-

Alfa Laval FrontLine is our premium range of plate heat exchangers for applications with the strictest demands regarding hygienic control as well as gentle product treatment, long operating time and superior cleanability. Suitable for applications with specific hygienic needs such as beverages, dairy and food, FrontLine plate heat exchangers are the superior choice for heat sensitive media. The flexible design makes for easy rebuild.

More information

-

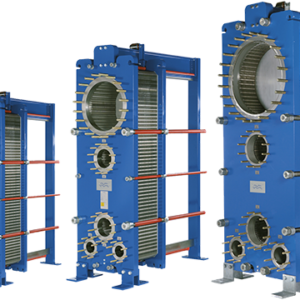

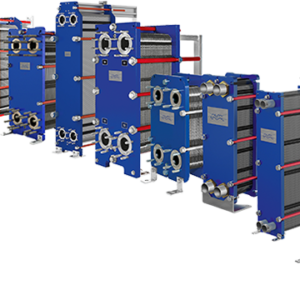

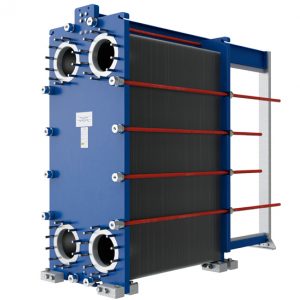

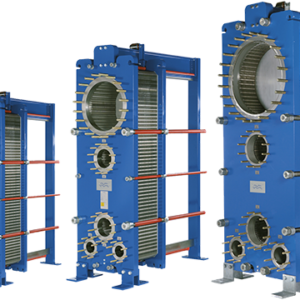

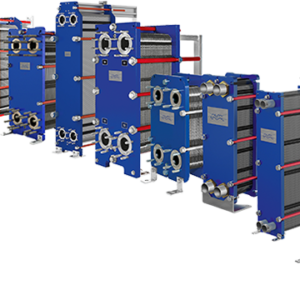

There is a wide variety of Industrial gasketed plate heat exchangers that can be used in all types of industries. The number of sizes, plate and gasket materials, and available options are enormous.

More information

-

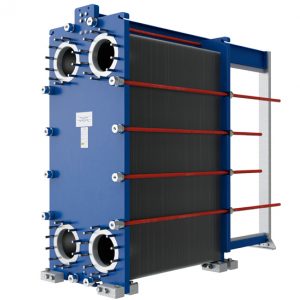

Industrial semi-welded gasketed plate heat exchangers are used when gaskets are not suitable as one of the process media. Semi-welded GPHEs can also take a higher design pressure compared to fully gasketed plate-and-frame heat exchangers.

More information

-

Alfa Laval M line of gasketed plate-and-frame heat exchangers is used for high design pressure (>10 bar/145 psi), such as in carbonated beverages. The large range of plate and gasket types complies with Food Contact Materials (FCM) requirements for pasteurization and other heating and cooling duties in hygienic and utility applications in the dairy, food, beverage and pharmaceutical industries.

More information

-

WideGap gasketed plate heat exchangers are designed for fibrous fluids and for fluids containing coarse particles. The wide gaps between plates allow fibers and particles to easily pass through the heat exchanger with minimum clogging.

More information