-

IMI PBM’s 2-Way Ball Valves are suited for pure process and clean steam applications. Forged and cast valves are low-controlled ferrite. Our unique Adjust-O-Seal® feature allows in-line valve adjustment to compensate for normal wear on valve seats.

More Information

-

IMI PBM’s 3, 4 and 5-way Multi-Port Valves are true multi-port valves with seals at every port. This design makes the multi-port ideal for flow switching operations. In some applications, this valve can replace as many as four ordinary 2-way valves, with corresponding savings in piping and fittings.

More Information

-

Cam-Line plastic-lined trunnion ball valves offer the same proven design benefits as the Cam-Tite product line, including tight shut-off, reliable stem sealing, and unsurpassed torque reduction—all unique features in a plastic-lined ball valve design. With a special Tefzel lining and optional PVDF coating, Cam-Line ball valves are well suited for highly corrosive applications within the chemical processing industry such as sulfuric and hydrochloric acid.

More Information

-

Cam-Tite ball valves are engineered to provide the very best performance for demanding hazardous and corrosive applications. Designed to overcome such inherent valve problems as high operating torque and stem leakage, Cam-Tite ball valves feature a unique, non-spherical ball with a bevel at the lip of the port. This configuration minimizes pressure on the seating areas, thus reducing cold flow and prolonging seat life.

More Information

-

IMI PBM’s Cryogenic Valves are fire tested to API-607 and exhibit superior performance through cooling and heating cycles.

More Information

-

Dia-Flo diaphragm valves are engineered for tough applications in the chemical processing, mining, power generation, pulp and paper, and water treatment industries. Dia-Flo weir-type diaphragm valves are utilized to handle media which is corrosive, erosive, or contains solids which tend to clog other types of valves. The weir-style diaphragm valve is used effectively as a control valve or where manual throttling of a fluid is desired.

Dia-Flo straightway-type diaphragm valves are utilized to handle abrasive and erosive media, fluids which contain up to 50% solids which tend to clog or abrade other types of valves. The straightway diaphragm valve can be supplied in a wide variety of body linings and diaphragms to address chemical compatibility of the service.

More information

-

IMI PBM’s Double Block & Bleed Valves provide true double positive isolation. This configuration provides the best technology for the most severe isolation services where double block and bleed is required. These valves are designed to ASME B16.34 and ideal for major oil refineries where safety and reliability are critical.

More information

-

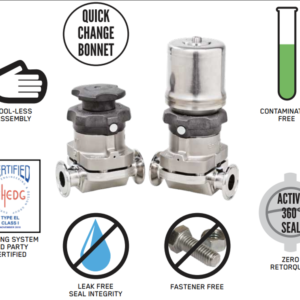

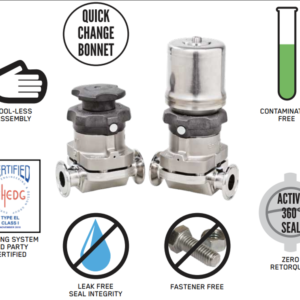

The Biopharm industry relies on hygienic diaphragm valves for demanding process applications due to their unique balance of clean-ability, drain-ability and pressure/ temperature capability. For more than 40 years the technology of these valves has changed very little. Advances in performance have been nominal as the basic design concept has remained the same: body, diaphragm, topworks, and four fasteners. This design requires experienced personnel and stringent maintenance practices to assure consistent, reliable valve performance. All while the industry is forced to increase productivity, extend preventative maintenance intervals, and reduce operating costs.

More Information

-

Fabri-Valve Figures C37 and F37 are some of the most popular knife gate valve configurations. Figure C37 knife gate valves through 24”, feature a heavy duty, rugged one- piece cast body, chest and flanges (except 5”, which is fabricated — F37). Sizes larger than 24” are fabricated from heavy plate.

The Figure C/F37 is available in all stainless steel (designated “S”) or with alloy steel wetted parts and carbon steel external parts (designated “R”). In sizes 1.5” through 24”, the “S” and the “R” share the same solid cast body. Sizes larger than 24” feature fabricated bodies configured to the service conditions.

The Figure C/F37 is available with the widest range of seats in the industry including: integral metal, replaceable hardfaced metal, rubber “D” ring, replaceable rubber, polyurethane, UHMW-P, and PTFE. Standard body materials include 304, 316, and 317L stainless steel. Special alloys such as 254 SMO® are also available. Special flange drillings are also available.

More Information

-

IMI PBM’s Instrument Valves are used for process flow or isolation of pressure gauge, orifice plates, flush rings and various measurement instruments. These valves are designed to ASME B16.34 and offer a higher performance solution to needle valves.

More information

-

The Pure-Flo brand is synonymous with the highest quality, precision engineered hygienic diaphragm valves. Pure-Flo valves offers superior hygienic processing components for the global hygienic processing industries (Pharmaceutical, Bioprocessing and Fine Chemical). Through both standard and custom designed valve assemblies, ITT Pure-Flo is committed to providing the best quality and value in engineered solutions for your unique flow-control needs.

The Pure-Flo valve product line began in 1978 as an extension to the venerable Dia-Flo product line. Since then ITT has been delivering to the Biopharm. industry a reliable and process proven stainless steel hygienic diaphragm valve.

More information

-

IMI PBM’s Self-Cleaning Valves with Adjust-O-Seal® technology thoroughly clean valve internals during CIP (Clean In Place) in the full open position. These valves also provide full, unobstructed flow and bidirectional, bubble-tight shutoff. This offers significant advantages over floating ball designs, as well as diaphragm and butterfly valves.

More Information

-

Skotch burner safety shut-off valves for oil-fired systems combine the function of three valves into one unit for increased safety and reliability while reducing installation time and labor cost. These valves have gained extensive usage in many industries, serving customers in power generation, pulp and paper, refining, chemical process, pharmaceutical/bioprocessing and pollution control markets. They have been utilized for over 25 years and are in service on boilers and burners around the world. Since Skotch Trifecta systems are custom built for each project, we are able to modify our standard offerings to suit our customer’s various applications. Whether it involves specialty materials or components, Skotch Trifecta valve systems will simplify your installation and operation while increasing safety and reliability.

More Information

-

IMI PBM’s 2-Way Tank Bottom Valves are suited for sanitary tank, vessel, and reactor applications. Angle Stem Flush Tank Bottom Valves provide actuator clearance on jacketed or insulated vessels.

More Information

-

IMI PBM’s Transmitter Isolation Valves (TIV) are specifically designed for any industry that must obtain pressure or level transmitter readings on tanks and vessels. Our valves are designed to ASME B16.34.

More Information